Curtain walls have become an essential element in modern architecture, offering a perfect combination of aesthetics, functionality, and energy efficiency. These lightweight, non-structural facade systems provide buildings with a sleek, contemporary appearance while protecting them from external environmental factors. Various types of curtain walls are available to suit different project requirements, including stick, unitized, and foldable systems. In this article, we will explore the different types of curtain walls and their unique features.

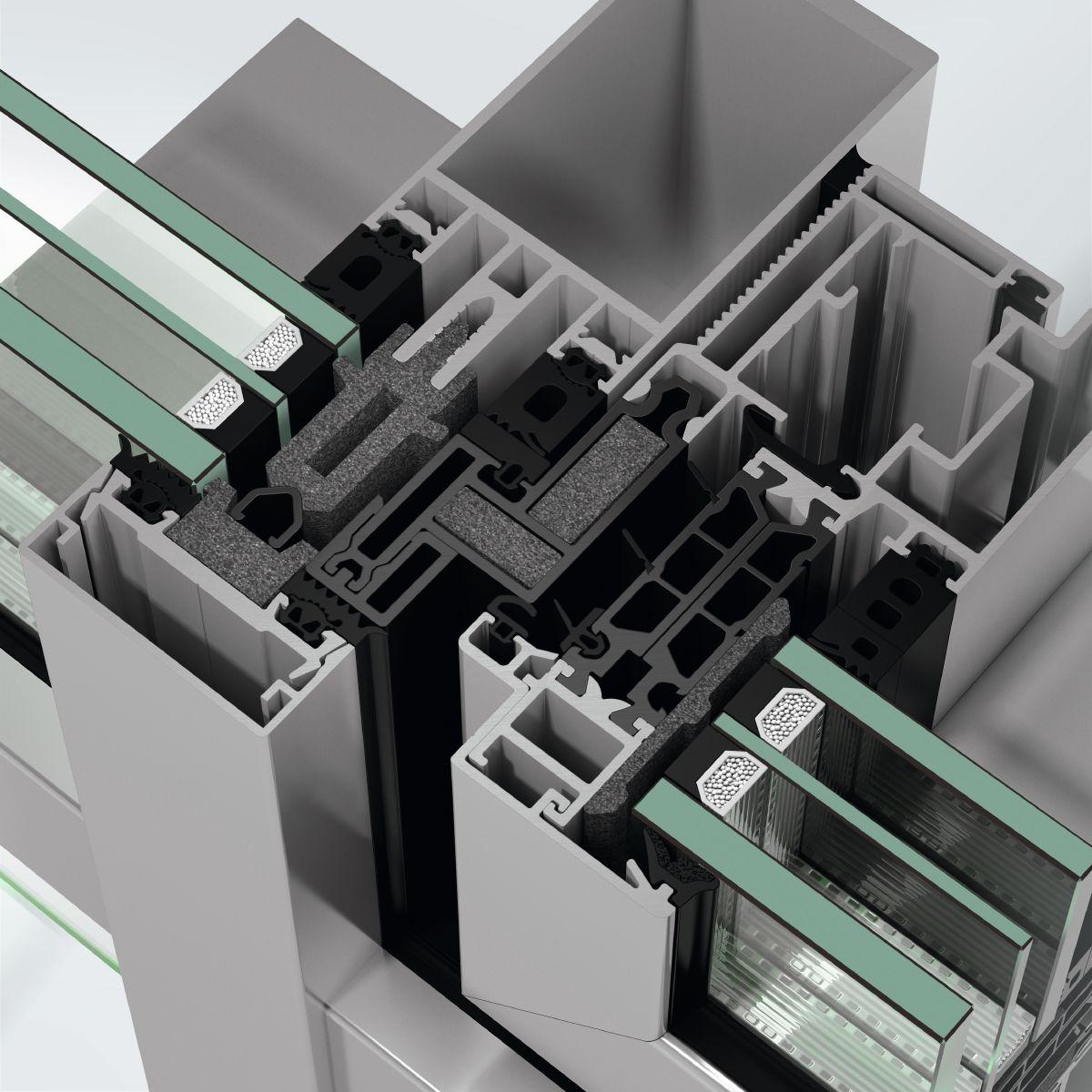

Unitized Curtain Wall

A unitized curtain wall is a prefabricated system where large sections of the wall are manufactured off-site and then transported to the building for quick installation. This type of curtain wall is commonly used in high-rise buildings due to its efficiency and precision.

Key Features of Unitized Curtain Walls:

- Factory Precision: Since the panels are assembled in a controlled environment, quality is assured.

- Fast Installation: Prefabricated units reduce on-site labor and construction time.

- Minimal Disruption: Ideal for projects with tight schedules and high-traffic locations.

Advantages of Unitized Curtain Walls:

- Superior Weatherproofing: Seals are applied in controlled conditions, ensuring better performance.

- Enhanced Structural Integrity: Stronger connections between panels enhance wind and seismic resistance.

- Sustainability: Prefabrication reduces construction waste and material usage.

Unitized curtain walls are a preferred choice for skyscrapers and large commercial projects requiring high performance and efficiency.

Stick Curtain Wall

A stick curtain wall system is one of the most commonly used types in low to mid-rise buildings. Unlike unitized systems, the stick system is assembled on-site, with individual components such as mullions, transoms, and glass being installed piece by piece.

Benefits of Stick Curtain Walls:

- Cost-Effective: Lower initial costs compared to unitized systems.

- Design Flexibility: Easy to adjust during installation, allowing for last-minute changes.

- Ease of Transportation: Components can be easily transported to difficult-to-reach locations.

Challenges of Stick Curtain Walls:

- Longer installation time due to on-site assembly.

- Higher dependency on skilled labor for proper execution.

- Potential quality control issues compared to factory-assembled unitized systems.

Despite these challenges, stick curtain walls remain a popular choice for architects looking for flexibility and cost-efficiency in their designs.

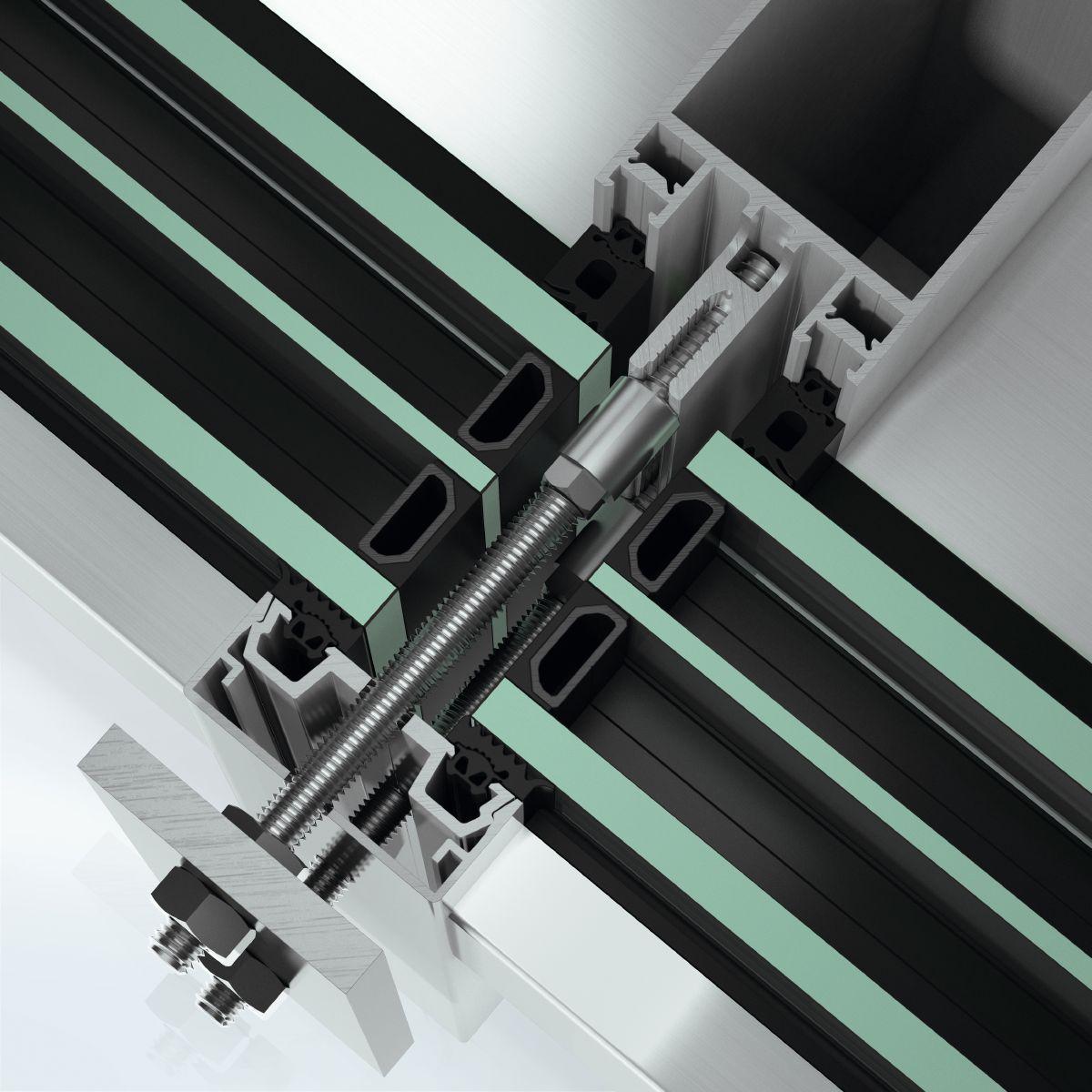

Stick Curtain Wall System

A stick curtain wall system refers to the overall design and engineering of stick-built facades. This system involves vertical (mullions) and horizontal (transoms) framing elements that support the glass or other infill materials. The flexibility of stick systems makes them ideal for projects with complex design requirements.

Components of a Stick Curtain Wall System:

- Mullions: Vertical elements that provide structural support.

- Transoms: Horizontal members that hold the glass panels in place.

- Glazing Units: The infill material, which could be glass, metal, or composite panels.

Applications of Stick Curtain Wall Systems:

- Office buildings

- Retail storefronts

- Educational institutions

Stick curtain wall systems offer a reliable and cost-efficient solution for various building projects.

Castle Curtain Wall

Unlike modern curtain walls, a castle curtain wall refers to historical defensive walls built around castles and fortifications during medieval times. These walls were designed primarily for protection and often consisted of thick stone barriers with battlements and towers.

Features of Castle Curtain Walls:

- Defensive Strength: Provided protection against sieges and attacks.

- Aesthetic Significance: Added grandeur and visual appeal to medieval structures.

- Multi-Layered Design: Included moats, gates, and towers for added defense.

Today, castle curtain walls are preserved as cultural heritage sites and serve as a reminder of medieval architectural brilliance.

Curved Curtain Wall Revit

A curved curtain wall Revit refers to the use of Building Information Modeling (BIM) software such as Autodesk Revit to design and visualize curved curtain wall systems. These walls add a unique aesthetic appeal by incorporating curved glass and framing elements.

Advantages of Using Revit for Curved Curtain Walls:

- Precision Modeling: Ensures accurate representation of curved elements.

- Performance Analysis: Helps evaluate energy efficiency and structural integrity.

- Visualization: Provides 3D renderings for better design communication.

Curved curtain walls are often used in landmark buildings, museums, and modern residential projects to create a distinctive architectural statement.

Conclusion

Choosing the right type of curtain wall system depends on various factors, including budget, project complexity, and aesthetic goals. Whether you opt for the flexibility of a folding system, the precision of unitized panels, or the affordability of a stick system, each option offers unique benefits. By understanding the characteristics and applications of different curtain wall types, architects and builders can create stunning and functional building facades.

FAQs

1. What is the main difference between unitized and stick curtain walls?

Unitized curtain walls are prefabricated off-site, while stick curtain walls are assembled piece by piece on-site.

2. Are foldable curtain walls suitable for residential projects?

Yes, foldable curtain walls are ideal for residential applications where flexible space solutions are needed.

3. What materials are commonly used in curtain wall systems?

Aluminum and glass are the most common materials due to their durability and aesthetic appeal.

4. How long does it take to install a unitized curtain wall system?

Installation is faster compared to stick systems, often reducing construction time by 30-50%.

5. Can curved curtain walls improve energy efficiency?

Yes, with proper glazing and thermal breaks, curved curtain walls can enhance energy performance.